Tough, Versatile Bulk Loading Systems - Save Time and Money

Optimized For Each Application

Choose application-proven screw, belt, drag, air slide or pneumatic conveying solutions and post, haunch or platform mountings that match the material and load-out location perfectly.

Built For Tough Duty

EconoLoaders™ are built to last. Operational lives routinely surpass 25 years in some of the most demanding environments with only minimal preventative maintenance.

Built For Maximum Versatility

Articulated EconoLoaders™ eliminate the need to move most transport vehicles, even when loading both trucks and rail cars in the same loading center. With nearly 360 degrees of pendant controlled, powered rotation and up to a 30 foot reach radius, EconoLoader can be horizontally and vertically positioned quickly and accurately over each loading hatch.

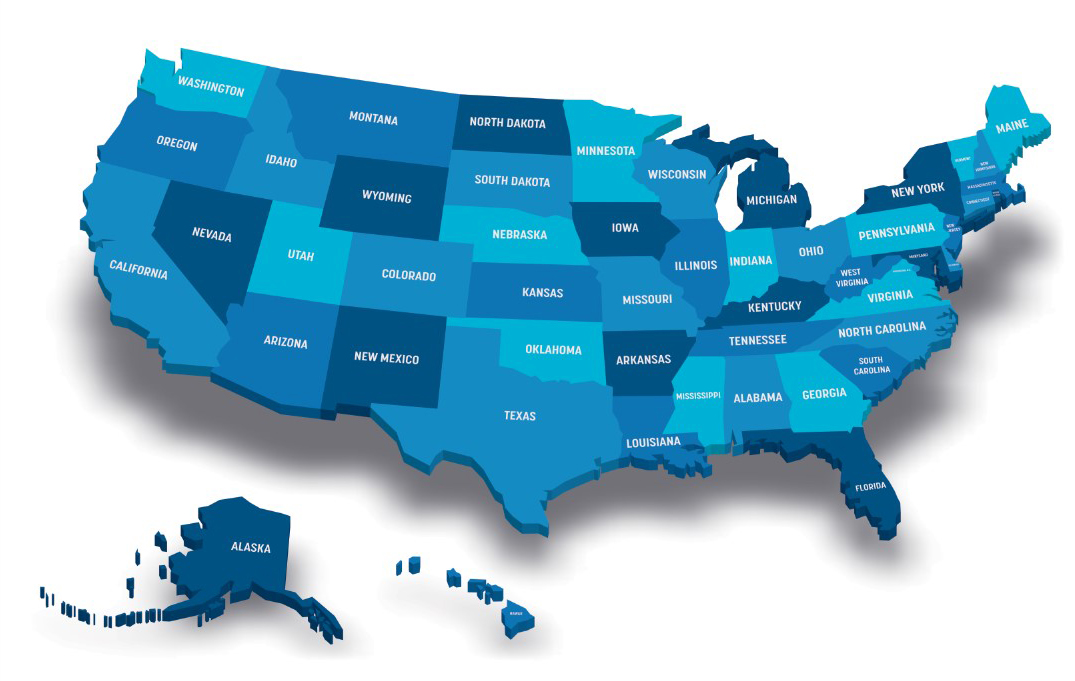

Over the years, DYNATEK has successfully handled a broad range of bulk solids loading requirements for companies like BASF, OMYA, Fagen Engineering, Akzo Nobel, Dupont, General Mills and Nucor Steel. So, challenge us with your loading needs and find out why DYNATEK Articulated Loading Systems are preferred by so many!

NEWS & EVENTS

DYNATEK™ Offers “Auto-Pilot” for Its Truck & Rail Car Loading Systems

New DYNATEK™ Dual-Discharge Shuttle Loader Maximizes Loading Efficiency for Hopper Trucks & Rail Cars

Dynatek Rail Car Loader

Hareza Technical Sales Chosen to Represent DYNATEK™ Loading Systems

Dynatek DDGS Loader at Work Making Isobutanol

The Tennant Company has become the newest member of its growing network of independent sales representatives

Ask Us About

Optional Features

Special Conveyor Designs

Custom Control Panels

Installation & Commissioning Assistance

Wear-Resistant In-Feed and Discharge Chutes