PRODUCTS

Loader performance optimization begins with selecting the best conveying technology. DYNATEK makes that easy by offering articulated loaders to accomodate your specific requirements.

EconoLoader - Belt Design

Belt-based loaders are often best for granular, irregular or sticky materials like coal, minerals, grain or fertilizer.

Learn More

EconoLoader - Screw Conveyor

Auger-based loaders are often used for dry, free flowing materials like salt, flour or sulfur that have a uniform particle size.

Learn More

EconoLoader - Drag Conveyor

Drag conveyor-based loaders are versatile enough to handle everything from grain to abrasive materials with large particle size variations.

Learn More

EconoLoader - Air Slide Conveyor

Air slide-based loaders use gravity and low pressure low volume air to convey fluidized materials like aluminum powder, fly ash, silica and phosphates.

Learn More

EconoLoader - Shuttle Conveyor

Shuttle conveyors are the perfect solution for single bay loadout areas and can be sized to deliver almost any loading rate.

Learn More

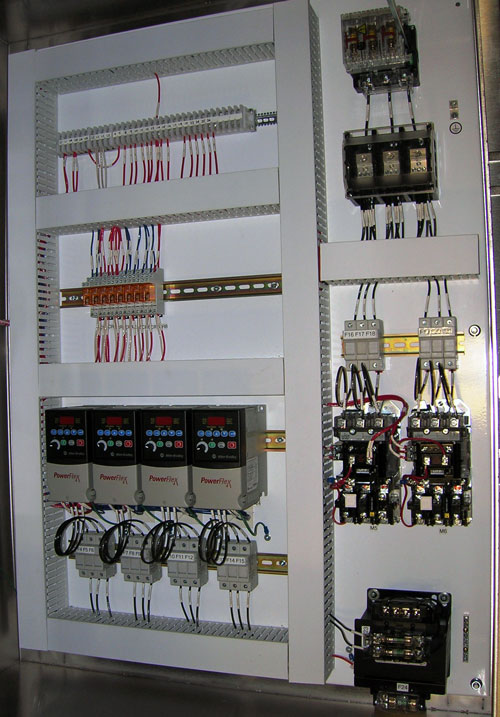

DYNATEK is fully equipped to provide control panels for its Loading systems. Working closely with each customer, motor starters, control voltage transformers, variable frequency drives, fusing, power disconnects, and control enclosure ratings are carefully selected for function, reliability and serviceability. Broader process integration and operational feedback can also be provided via PLCs and custom programming.

Sign up for news updates

Ask Us About

Optional Features

Special Conveyor Designs

Custom Control Panels

Installation & Commissioning Assistance

Wear-Resistant In-Feed and Discharge Chutes

Ask About DYNATEK System Options